| |

|

|

|

|

| CANTILEVER

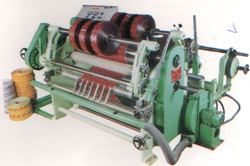

DIFFERENTIAL SLITTER REWINDER MODEL-1003 |

|

|

|

| The canti duplex shaft slitter

rewinder is a cantilever type which incorporates a range of superior

design feature that ensure the highest possible quality for the final

split roll independent rewind tension control through non contact

ultra sonic techniques for diameter measurement and unique core lock

for differential slip running speed. |

|

| The design incorporate the

three motor control system & unwind pneumatic brake with load

cell feed brake Digital Edge/ line guiding to achieve high speed correction. |

|

| Slitting

Line for: All type Film, Paper, Foil, Non Woven, Leathar, Rubber and

Textile Industries |

|

Drum Type Center Cum

Surface Slitter Rewinding M/c.

Model: PTE Multi Slit – 1000 |

| |

| The center surface machines are often

chosen for very narrow slit width application as they

are capable of slitting down to 6 mm. The machine geometry

provides full material support from the slitting area

to the rewind. |

|

|

|

|

|

Open End………….Cantilever

Center Shaft Slitter

Rewinder M/c.

(Doctoring / Inspection M/c.) |

| |

| Model: PTE Slitt Well – 1001 |

| |

| Narrow width cantilevered machine

can be equipped with razor, shear, rotary die and crush

cutting. Other options such as edge guiding, automatic

tension control and differential rewinding ensure total

machine flexibility.

Duplex center winders often provide a cost effective

solution for narrow web applications. The machine

can be extremely versatile and the short, accessible

web path is ideal for short production runs |

|

|

|

| Strech

Film Slitter Model : 1002 |

|

| PEE TEE ENGINEERS |

| PTE has been manufacturing miscellaneous

slitter rewinders for the film, foil and packaging material

industry |

| |

| One of the best-known models is the

PTE Accu Splice, a universal machine, which offers various

rewinding system. |

| |

| PTE has completely redesigned this machine

maintaining, however, the decisive technical advantages. |

| |

| These short are short web paths inside

the machine, in particular downstream of the slitting

section, which ensures excellent winding results. |

|

|

|

| Salient Features : |

• Most Versatile Model providing combination

of Duplex Center cum surface rewing system.

• Consistently

flawless slit rolls by providing center drive drum to maintain

Fixed minimum distance between slitting and rewind point.

• Constant line speed cause constant tension rolls.

• Two rewinding shafts carried on swinging arms are center

driven through adjustable slipping clutch.

• Counter

balance system to adjust pressure between rewind reels and center

drum.

• Suitable for off clipper / Slippery / Stretchy

material.

• In special case rewinding shaft can be

supplied with provision of Individual Differential slip assembly

for each slit reels.

• Slitting methods as per customer

requirements like : Scissor cut / Crush cut (Circular knives)

Razor Blade Slitting System |

|

|

|

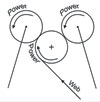

| CENTER & SURFACE REWINDING |

| |

| The rewind shafts are center-driven

with the help of Friction clutch and further drive is

given to surface of winding reels by pressing them against

driven surface roller. |

|

| |

|

|

| DUPLEX SURFACE REWINDING |

| |

| Here rewing shafts loaded with cores

are pressed against driven surface roller and only surface

of winding reels get positive drive from surface roller.

This method provides. |

|

| |

|

|

| CENTER REWINDING WITH MINIMUM GAP |

| |

| Rewind reels are center driven through

friction clutches and this method provide the ability

to wind off caliper materials or those that cannot be

surface wound. With help of special ratchet pinions on

Rewind Shaft carrying arms, The rewind reels are place

slightly away from time-to-time, as reel diameter increases. |

|

| |

|

|

| CENTER REWINDING WITH FIXED GAP |

| |

| This method of rewinding is similar

to above mode except that Rewind Shafts are kept away

from the Surface Roller at a fixed distance. |

|

| |

|

|

|

|

1. UNWIND ROLL

2. PNEUMATIC BRAKE OR AUTO TENSION CONROL BRAKE

3. EDGE GUIDE CONTROL UNWIND FRAME-STRUCTURE (MOVABLE) OR FIX

UNWIND FRAME.

4. PNEUMATIC OR LINE SENSOR

5. DANSING ROLLER

6. HCP NIP ROLL

7. RUBBER ROLL

8. SLITTING ASSEMBLY

9. ADJUSTABLE PRESSURE ROLL

|

10. HCP DRUM ROLLER

11. REWIND ARM (BOTH SIDE)

12. FINISH REWIND ROLL

13. COUNTER BALANCE SYSTEM

14. CLUTCH ASSEMBLY/ MECHANICALLY / MEGNATIC BREAK MOTOR

FOR REWIND TENSION

15. EDGE TRIMING

(A) PNEUMATIC CYLINDER

FOR ARM LIFTING

(B) BOTTOM CUTTER

(C) TOP CUTTER

|

|

|

| Motor

Drive |

| Single Motor Drive |

Two Motor Drive |

Three Motor Drive |

|

|

|

|

|

| Specifications : |

| Web width |

300/400/600/1000/1500/2500 mm |

| Max. Dia. of Stock roll |

600 mm to 1500 mm |

| Min. Slit width |

10 mm |

| Dia. of finished roll |

350/600/1000 mm |

| Operating speed |

10/150/250/350 mt / min |

| Power requirement |

As per Model. |

|

| |

| Standared

Slitter |

|

The

versatile machine from PeeTee for ultimate slitting and rewinding

work, ACCUSPLICE ensure perfect slitting of rolls with consistent

flawless quality and constant Line speed. It is available

in adaptable models to suit your requirement.

|

| |

|

|

| Salient Features : |

| Most versatile model providing

combination of duplex centre cum surface rewind system. |

|

Consistently flawless slit rolls

by providing centre driver drum to maintain. |

|

Fixed minimum distance between slitting and

rewind point. |

|

Constant line speed cuases constant tension

rolls. |

|

Two rewinding shafts carried on swinging arms

are center driven through adjustable slipping clutch. |

|

Counter balance system material. |

|

In special case rewinding shaft can be supplied

with provisional of individual differential slip assembly for

each slit reels. |

|

Slitting methods as per customer requirements

like : Scissor cut / Crush cut (Circular Knives) / Razor Blade

Slitting system. |

| |

|

| 1. |

Unwind Roll |

| 2. |

Auto Tention Control Brake or Mechanical Brake

|

| 3. |

Edge Guide Control unwind frame structure

(Movable) or fix unwind frame. |

| 4. |

Pneumatic or Line Roller |

| 5. |

Dancing Roller |

| 6. |

NIP Roller Set |

| 7. |

Slitting Attachment |

| 8. |

Adjustable Pressure Roll |

| 9. |

Drum Roller |

| 10. |

Rewinding Arm (Both Side) |

| 11. |

Clutch Assembly/Mechanically Megnetic for

Rewind Tention |

| 12. |

Counter Balance System. |

|

|

| Canti

Lever Slitter Rewinder (Model PTE 3) |

|

| Sliting and

rewinding machine model accusplice |

|

Pee Tee Make moveable unwind frame structure.

|

|

Edge Guiding system/line guiding system. |

|

Bearing bracket for Air shaft. |

|

Air shaft for 76mm core. |

|

Max. Reel weight 1000kg. |

|

One unwind shaft complete with Reel cones, Check Nuts

and Gear (Extra.) |

|

|

|

|

| SLITING UNITS |

|

Type of slitting : Razor in groove slitting system.

|

|

One full width capacity grooved roller. |

|

Trim removal system : 2 HP blower with full width Pipe for

trimming alongwith a trim INjector unit. |

|

Control Switch of teh trim blower is incorporated in the control

panel. |

|

Quick and easy system for change over from one Slitting mode

to anothesr and from one slit width to another. |

|

|

| NIP UNIT |

|

One full width capacity hard chrome plated steel

roller of 170mm diameter. |

|

One full width capacity rubber roller of 150mm diameter. |

|

Pressure is Pneumatically applied from the operation side

of the machine. |

|

|

| REWINDER |

|

Type of Rewinding : Duplex Cantilever Differential

Winding. |

|

Max. Rewind roll diameter : 900MM |

|

Two Rewind shafts complete with core holders, brake liners

and M S washers for Max. 5 Cuts. |

|

Two lay on rollers are provided with Pneumatically operated.

|

|

Rewind, Slip ring, Pressure also controlled by Pneumatic.

|

|

|

| ELECTRICALS |

|

5 HP Control for Powerpack of Edge guiding. |

|

The Control Panel has controls for the speed setting, trim

removal blower and emergency stop. |

|

One A. C. motor of 2 HP for the trime removal nolower. |

|

Wiring of the machine is not in the Scope of supply. It has

to be expected by the customer. |

|

|

| Mini

Accu Splice (Narrow Web Slitter Rewinder) |

| |

| Specifications : |

| Web width |

300 to 800 mm |

| Max. Dia. of Stock roll |

600 mm. |

| Min. Slit width |

10 mm. |

| Dia. of finished roll |

350 mm. |

| Operating speed |

up to 150 mtrs. per minute. |

| Power requirement |

2 HP

3 Phase, 50 cycles, A.C., supply |

|

|

|

| Optional : |

|

Auto Tension Control

for unwind unit. |

|

P. T. Web Edge Guide system. |

|

Pneumatic system for arm. |

|

Air Shaft for unwind station.

|

|

Line Edge |

|

Guide system. |

|

|

|

|

|

| Duplex

Center Shaft Type Slitter Rewinder |

|

|

Max/ Web Width. |

up to 1200mm |

|

|

Tension Rang. |

5-25 Kg. |

|

Unwind Reel dia |

1000 MM |

|

Rewind Reel dia |

500 MM |

|

Max. Machine

speed (Design.) |

200 mtr. P. Min. |

|

|

| 1) UNWIND STATION |

One Mechanical / Automatic

Web guiding system (As per detail-Annex_B)

One mechanical / Automatic Braking (As per detail-Annex. B)

One unwind shaft 50mm dia (50mm)

One set check nut, core-cone and gear. |

| 2) MAIN MACHINE |

Min. slit width 100mm. |

| 3) TYPE OF SLITTING |

Razor Cutting.

Top & Bottom cutter with spacer (As per details-Annex-B)

|

| 4) TRIM REMOVING |

Trim inkjector / Tripe pipe with

1HP Blower

With one full width Capacity, hardchrome plated steel |

| 5) NIP UNIT. |

With one full width Capacity,

hardchrome plated steel roller 150mm dia and one full width

capacity 150mm dia synthetic rubber roll. One pressure adjusting

device Pneumatic for NIP roller (As per details Annex-B) |

| 6) REWINDING |

Type of Rewinding duplex differential.

2 Nos Rewinding shaft 50mm dia with 2 Set check nut, core cone

bearing block and gear.

Rewind control through, two clutch assembly mechanical.

Two lay on roll.

Distance washer as per rell cut (Require)

Individual slip ring arrangement as per require cut.

Control Panel (As per detail Annex_B) |

| 7) CONTROL PANEL |

Variable D. C drive or A. C. drive

with Blower & Powerpack control switch.

One pneumatic Panel for cylinder without F. R. L Unit. |

|

|