|

| |

|

|

|

|

| Coating

& Lamination Machine |

|

| Salient Features : |

|

The new line offered by Pee

Tee Engineers is considered very economical in investment

also very simple to operate and maintain. Ideal to handle

small type jobs and is most suitable for flaxible packaging

industries. |

|

Gravure coating system with reverse arrangement.

|

|

Cantiliver type inpresson pressure assembly

actuated with pneumatic piston rubber roll, Doctor blade and

Nip Roller. |

|

Fully insulated glass wool fitted in the

panel (Top, Side & Bottom) for controlling heat loss. |

|

One and one slit type air flow arrangement.

Divided equally are placed against roller for proper web support. |

|

Exhaust Nozzles are equally distributed

through-out the length of drying chamber. |

|

Digital temperature controller with indicator

& P T 100 sensor for each zone. |

|

Inside heating for Nip steel roller. |

|

P. T. Web SRA system for controlling the

Web after the Drying tunnel. |

| |

|

|

| High efficiency sectional

tunnel and airfloation exhaust through one & one counter against

the driver roller with pneumatic lifting. |

|

P.T. presents the ultimate

lamination Coating Machine Webmate. Which is easy to handle, install

and operate, It takes care of large quantity of lamination work

in a non-messy and organised manner. |

|

| Optional Attachment : |

|

PT Chaiser system for controlling

two webs at the same time. |

|

Pneumatic Lifting for drying tunnel hoods

for easy guiding and also cleaning of the idle roller. |

|

Cat-Walk arrangement along with the machine

length to provide easy access to the drying tunnel. |

|

Water cooling roller is provided at Rewind

unit. |

|

Tension controller for the unwind unit.

|

|

Special type cooling torck for surface winder. |

|

Flame proof lacquer circulating pump. |

|

Thermic fluid heating system. |

|

Positive drive for all dynamically balanced

roll through out tunnel with arc form to give proper web support

and eazy acess of web materials. |

|

Wrinkle removing device (BOW EXPANDER/STRIP

EXPANDER) |

|

May bar coating arrangement. |

|

Wet Nip arrangment. |

|

Programmable temperature controlling for

each zone of tunnel. |

|

Various types of coating systems on Customers'

request. |

|

|

| Vertical

Coating Machine |

|

|

| (1) AIR INLET |

(10) TENSION REWIND DRIVE |

| (2) AIR JET |

(11) REWINDER |

| (3) GUIDE ROLL |

(12) PNEUMATIC SENSOR |

| (4) HOT AIR CHAMBER |

(13) LOAD CELL SENSOR |

| (5) SRA |

(14) UNWINDER TENSION BRAKE |

| (6) PRESSURE NIP ROLL |

(15) 2ND UNWINDER |

| (7) HOT NIP ROLL |

(16) 1ND UNWINDER |

| (8) PRE-HEATING |

(17) EXHAUST DUCT |

| (9) LAY-ON ROLL |

(18) PRE-EXHAUST |

|

|

| Hot

Melt Coating |

|

| |

| Roll

to roll prossece control equipment pre and post prosece machinery

different type of unwind inspection & Rewind (Batching) |

| |

|

|

| Pilot

Coating & Laminaton M/C |

|

|

| First time in India Introducting lab testing plant

|

| The new line offered

by PTE is considered very economical in investment, running cost,

also very simple to operated and maintain. Ideal to handle small

type jobs and is most suitable for lab testing.

|

| Salient Features : |

- Fully insulated glass wool panel of Drying tunnel.

- Coating facility through Gravure Maybar.

- Reverse roll, Air Knife Three roll, Doctor blade.

- Lamination with any material.

- Individual Blower with Heater and Temp Controlelr.

- Unwind & rewind as per requirement.

- Up to 400mm Width.

- Variable D. C. Drive.

- Pneumatic cotnrol at required Point.

- One and one type Exhaust system.

- Surface and center windign facility.

- Web guiding system (Optional).

- Synchronised drive (Optional).

- Tension control system (Optional).

|

|

|

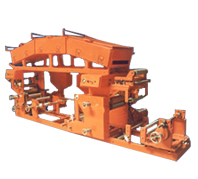

| AUTODOCT |

|

The Developed Doctoring Machine

From the House of P.T. : |

| In any paper, firm &

foil conversion industry, "SLITTING" is invariably the

last operation to be performed. At the time of slitting, irrespective

of the brand and type of slitting machine employed, ten to twelve

percent of the output (i.e. One out of 10 or 8 slit to size bobbins)

is not of saleble quality. This is a Harsh practical fact and the

reason thereof are quite well known. The model is specially designed

for correcting badly wound roller for removing the misregistered

and rejected material before it goes to final delivery, in order

to rectify salvage such rejection, the Doctoring machine has been

specially developed through the R & D efforts at P.T. |

|

| Optional : |

|

Presetable Digital Counter meter

for measuring the length |

|

In line slitting arrangement with trim suction

blower. |

|

Batch counter for label stock with Datalogic

Touch less colour mark sensor. (Micro processor based) |

|

Strubo scope for easy & steady viewing.

|

|

Ink jet printer with mounting bracket. |

|

Ink jet Printer's dryer. |

|

| |